|

|

|

|

|

|

| |

The future of load cell weighing

27

March

2012

|

| |

Introduction

Introduction

Weight (or more correctly Mass) is one of the three fundamental measurands, together with Length and Time. Its accurate measurement is vital to the world we live in, providing important controls in manufacturing, trade and commerce. So how has it changed over the years and what does the future hold?

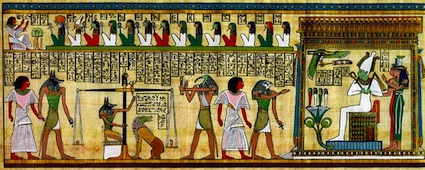

Some of the first clear documentary evidence of formalised weighing can be traced back to the Sumerian and Egyptian civilisations over 4000 years ago. The ancient Egyptians believed that when they died, they would be judged on their behaviour during their lifetime before they could be granted a place in the Afterlife. This judgement ceremony, overseen by the god Anubis was called "Weighing of the Heart". In this, the heart of the deceased was weighed on a pair of enormous balance scales against a feather taken from the headdress of Ma'at, the goddess of truth, order and justice. If the heart balanced against the feather then the deceased could pass through to the Afterlife. If it were heavy with the ‘weight of wrongdoings’, the balance would sink and the heart would be grabbed and devoured by Ammut, "the gobbler’, a terrifying beast that sat ready and waiting by the scales. Interestingly the weighing results were diligently written down by the god Thoth and this is probably the first reference to weight data management. One can only imagine the techniques employed to influence the outcome of the weighing!

Fast forward a few thousand years and weighing technology changed very little until increased transport and trading during the industrial revolution initiated a significant demand for more accurate and versatile mechanical scale designs.

The strain gauge load cell

A key turning point in weighing technology came with the development of the strain gauge load cell. As this ubiquitous product approaches its 70th birthday, it is difficult to identify any other industrial product which has had such a long standing technological impact on industry and commerce. Patented, by Arthur ‘Mike’ Thurston of the Cox and Stevens Aircraft Corporation, Mineola, New York, the first compression strain gauge load cells were conceived in 1942 for determining weight and balance characteristics of military aircraft during the Second World War. (US Patent no 2,488,349 was filed in 1944 and granted in 1949).

Although their commercial use in industrial weighing followed shortly afterwards, growth was limited by the lack of suitable signal conditioning instrumentation. This meant that mechanical scales continued to play an important part in many areas of weighing even into the 1970’s. It is still difficult to believe that electronic weighing only came into everyday use in the early 1980s. Today load cells and electronic weighing are at the heart of industrial and commercial weighing in equipment as diverse as weighbridges, belt weighers, bench scales, crane scales, silo weighing systems, process weighing systems, retail scales and laboratory scales

"The reports of my death are greatly exaggerated” Mark Twain

This famous line could well apply to the strain gauge load cell. Pundits have been predicting its demise for several decades, especially when low cost microchip electronics burst onto the scene, changing our lives for ever.

However the original designs have, in evolution terms, changed little and have stood the test of time over this extraordinary period of invention and development.

Although important improvements have been made in load cell design and strain gauge manufacturing techniques, the fundamental principle of using a Wheatstone bridge arrangement to measure resistive changes caused by strain level changes in metal elements continues to provide accurate and reliable weight data.

Digital load cells have made an important contribution to load cell development, especially in higher capacity systems. However these are not the lower order devices envisaged three decades ago and still rely on precision bonded strain gauges for weight signal derivation. Their main advantages are in areas such as system calibration and troubleshooting rather than in low cost manufacture.

But what of the future?

In the 1980’s it was widely believed that the strain gauge would be replaced by alternate technologies such as thin film deposition, with microprocessors carrying out necessary compensations to enhance performance. Although such technologies are now extensively used in smaller load and pressure sensors, they have failed to influence load cell designs for industrial applications.

The major changes in weighing over the past three decades have come in the processing and management of weight data. Here significant advances have been made, making use of modern electronics, software developments and communication technologies, especially the world wide web.

How will weighing change over the next thirty years

One of the fundamental barriers limiting significant changes in industrial weighing technology relates to the physical requirements to support the load being weighed. A prime example of this is the weighbridge where the structure supported on load cells has to survive the rigours of vehicles weighing upwards of 50 tonne driving onto the deck and then braking.

In parallel, strict international guidelines clearly define metrological requirements for a large sector of weighing equipment for trade use. Even if legal for trade requirements are not mandatory, increasing demands on accuracy have a strong influence on development.

So what are and could the alternatives be to traditional load cell weighing? Chances are the technologies that will eventually replace the humble load cell and revolutionise weighing have yet to be discovered.

Beam me up Scottie

Vehicle weighing may be one area where market forces influence the evolution of new weighing technologies. Perhaps magnetic or plasma techniques will evolve to take the place of platforms and support the vehicle above the ground, whilst measuring its weight. Or maybe sophisticated, yet low cost, sensors in the vehicle tyres will make the traditional steel or concrete weighbridge redundant. Whatever the solution, it has a mountain to climb in terms of environmental compatibility, accuracy and overall reliability. In the shorter term, new composite materials may come to the fore to simplify weighbridge structures and reduce the dependence on steel or concrete.

Onboard weighing systems have grown in popularity for certain industry sectors but their cost and technical shortcomings are currently preventing wide spread adoption. Alternative technologies for calculating vehicle loads are in their infancy. One such technology scans the load in the vehicle from above and calculates the weight based on volumetric versus density data. This can provide useful data in areas such as quarrying, but such techniques are very dependent on load uniformity and are affected by factors such as product density variances.

Conclusion

One thing is clear. Future designers will need to think outside the box if major changes are to take place in industrial weighing. When we review this in another thirty years, major changes will have taken place in the world around us as our dependence on oil has to change. However the requirement to measure the fundamental parameter of weight within a high degree of accuracy will still be there. Hold onto your hats, it’s going to be an interesting time.

For further information from Weightron Bilanciai Ltd, please visit: www.weightron.com |

|

|

| |

FactoryEquipment.com are not responsible for the content of submitted or externally produced articles and images.

Click

here to email FactoryEquipment.com about any errors or omissions contained within this article. |

| |

|

|

|

|

|

|