|

|

|

|

|

|

| |

Millions of Devices Can’t Be Wrong

23

January

2013

|

| |

The market for industrial networking is now over 20 years old, and has changed beyond recognition since the early days. However, its development has confounded the conventional economic theory: far from the expected rationalisation, we have more networks and protocols than ever according to David Folley of HMS Industrial Networks.

The market for industrial networking is now over 20 years old, and has changed beyond recognition since the early days. However, its development has confounded the conventional economic theory: far from the expected rationalisation, we have more networks and protocols than ever according to David Folley of HMS Industrial Networks.

It is estimated that there are over twenty main open networks and fifty proprietary ones. As end users increasingly specify their preferred control automation network it presents a real dilemma for device and equipment makers who must be able to supply their machines or devices with the ability to communicate with any network or between different networks.

Conventional wisdom is to use a modular communication gateway, and with millions of such devices already in use, this popular approach is readily available for almost all open and proprietary networks.

There will however be times when a modular solution is inappropriate, due to its physical size or cost. For this reason gateway manufacturers have also started releasing their core technologies in the form of chips and dedicated board (brick) based solutions. These are ideal for high volume and PCB level integration.

Without significant investment or risk

In manufacturing, high performance industrial automation networks are increasingly in demand to meet the need for faster control, reduced cycle times, and to support higher levels of secure data transfer. This demand is rising as producers seek to optimise and integrate their automation systems to accommodate traceability, increased use of robots, and to cope with expected increases in monitoring due to legislation and safety requirements.

Whilst the hardware manufacturers promote their proprietary systems for speed and reliability, open networks have gained in popularity because no single producer provided a range of connected devices for every application, and because end-users were seeking plug-and- play style automation for all networked devices. The benefits to users of open networks include:

• Selectivity of best in class products from a range certified compatible products

• Cost reductions by a multi vendor platform

• Long assured lifetime of technology and support

• The opportunity of joining a user group and participating in new developments

Earlier problems such as who is responsible if a device connected to a network does not produce the expected performance have largely abated as the leading network gateway manufacturers certify their gateway devices with the open network associations such as Profibus, ODVA and so on.

Gateway communication devices are particularly attractive to third party manufacturers seeking to integrate networking into their devices. Previously there were a number of considerations before the development of network compatible versions of their products, such as:

• Which of the seventy or so networks are most important to your business?

• Do you have the in-house expertise to develop a range of network interfaces?

• Do you have the development capacity or budget to develop a range of network interfaces?

• Are projected volumes high enough to meet target ROI?

• Can we manage the maintenance, certification and future support?

Because of this, equipment makers have increasingly turning to established specialist companies that develop, produce and market intelligent communication technology for automation equipment. These specialist companies are leaders in providing reliable solutions to connect devices to any major network protocol and enabling interconnection between different industrial networks.

They work closely with both manufacturers and the open network associations to ensure their gateway products are fully compatible, and routinely conformance tests all such devices of their manufacture. From the users perspective selecting such expert partners offers access to the latest technology without significant investment or risk.

Choice of deployment

There are many considerations in selecting a suitable gateway device. For example in higher volume applications an embedded device may be most appropriate whereas connecting a smaller number of disparate devices may require a different solution.

Embedded fieldbus/Ethernet interfaces

Module

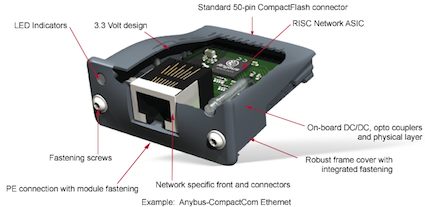

A typical embedded interface module utilises a plug-in design in which the different network interfaces can be plugged into the product’s control board by way of a standard CompactFlash connector. Different plug-in modules provide device makers with interfaces allowing connectivity to the leading industrial networks.

As the modules’ software interfaces are network protocol independent, automation devices with a suitable slot can use any compatible plug-in module. This allows the host application to support all major networking systems using the same software driver, without loss of functionality or performance. For example, you can simply replace the Profibus module with an EtherNet/IP module and be instantly connected to that network without the need for hardware and software changes in your automation device.

These devices use a custom developed network communication processor to deliver a flexible high performance interface with low power consumption, compact size and competitive pricing. The performance and flexibility provided by them offer a fast time-to-market of between one and three months and are ideally suited for automation device manufacturers. Typical applications include HMIs, robot controllers, drives, micro PLCs, valve manifolds, instrumentation, weigh scales, temperature controllers, bar-code scanners, I/O blocks, welding controllers etc.

Modules are categorised into two types: active modules that support the fieldbus and Ethernet networks and the application interface can be accessed either by the dual-port RAM or fast serial line. Passive modules provide the physical layer network interface and transparent pass-through for serial data between the network and host. These are available for RS-232, 485, USB and Bluetooth. Both are installed in the host device using the standard CompactFlash connector.

Chip

The recipient device uses a single chip high performance network processor. This ASIC has a high performance, low power RISC processor including Profibus, Ethernet, CAN and other communication interfaces as well as internal RAM and Flash memories.

The device is for mounting in the PCB and requires the customers to supply a few add on components for integration with the host processor.

Brick

The brick type interface is for device manufacturers who are looking for a semi-integrated solution where connector flexibility, size, cost and time-to-market are key elements, and gives users the flexibility to add their own connectors on the network side. (DSUB, RJ45, M12 etc)

It incorporates the network processor and components required for a fast, cost effective fieldbus or Ethernet connection for the industrial device. The brick includes network functionality and is ready to communicate, which results in a reduction of development efforts and a fast time-to-market.

Industrial Ethernet made easy

High performance versions are also available for high-end industrial Ethernet and fieldbus applications requiring fast network cycles. They use a flash-based, single chip network processor that includes a high-performance ARM core and an FPGA (field programmable gate array) fabric.

The FPGA fabric is used to implement the various real-time Ethernet interfaces while the ARM core is used to run the protocol and application stacks. Since they are flash-based, the devices can be re-programmed for several different industrial Ethernet networks by simply downloading new firmware. This reduces systems development time because there is no need for redevelopment for each additional network.

These faster processors enable practically “zero delay" between the device and the network making them ideal for high performance, synchronized applications such as servo drive systems.

Dedicated technical support is available for implementers, and the fact that millions of embedded network gateway devices are already in use is a clear sign that the solution can’t be wrong.

For further information, please contact:

HMS Industrial Networks Ltd The Venture Centre, Sir William Lyons Road, Warwick University Science Park, Coventry CV4 7EZ UK SALES DEPARTMENT Phone: +44 (0) 1926 405599 Fax: +44 (0) 1926 405522 sales@anybus.co.uk Read more on www.anybus.com |

|

|

| |

FactoryEquipment.com are not responsible for the content of submitted or externally produced articles and images.

Click

here to email FactoryEquipment.com about any errors or omissions contained within this article. |

| |

|

|

|

|

|

|