|

|

|

|

|

|

| |

Electric heating is cheaper and more controllable

3

June

2013

|

| |

Everyone knows that the unit price per kilowatt hour of gas is cheaper than that of electricity, but the gap has been closing over the years. Despite the lower cost of gas, electric heating is making big inroads into the ovens and furnaces market – a market once dominated by gas heating.

Everyone knows that the unit price per kilowatt hour of gas is cheaper than that of electricity, but the gap has been closing over the years. Despite the lower cost of gas, electric heating is making big inroads into the ovens and furnaces market – a market once dominated by gas heating.

There are several advantages of electric heating over gas. Electric heating provides much better control, particularly if using a thyristor or solid state relay (SSR). Even with a fully modulating or valve positioning burner the control swing is quite noticeable in a gas oven.

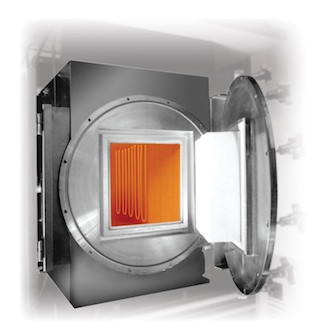

If tight uniformity is required, then oven and furnace manufacturers would always recommend an electric oven because controlling gas burners is much more difficult. As a rough rule of thumb, we regard anything up to 800 degrees centigrade to be an oven and anything above to be a furnace for heat treatment.

In the case of a furnace, the construction changes from a steel frame with an inner skin and outer skin of sheet steel with lagging in between below 800 degrees, to a steel frame with brick work above 800 degrees. Gas heating would be impossible in a vacuum furnace where contamination needs to be avoided.

Electric heating is much more efficient. Even with the modern burners there is a certain amount of wastage for the gas supplied to the burner through pipes and suchlike, so you don’t get out all that you put into it. With electric heating, you only use the amount required.

The initial cost of the oven is lower for electric and typically a gas oven is around 20 percent more expensive. This is due to a couple of things. Firstly, the burner requires a combustion chamber of some sort. This can be either above or external to the oven chamber and ducted into the working area, or through a tube direct into the oven duct, therefore increasing the duct size along with the oven size.

Secondly, there are more safety factors to consider. By law an oven will require an explosion relief panel as well as a fresh air inlet and a volatile outlet to allow the spent combustibles to escape to atmosphere. This means fewer emissions with electric heating.

So before dismissing electric heating for ovens and furnaces as being too expensive, it pays to look at the total cost of operations, not just the unit price per kilowatt hour.

For further information contact: Jez Watson,

CD Automation UK Ltd, Unit 9 Harvington Business Park, Brampton Road, Eastbourne, East Sussex, BN22 9BN Telephone: +44 (0) 1323 811 100 Fax: +44 (0) 1323 879 012 www: http://www.cdautomation.co.uk e-mail: jez.w@cdautomation.co.uk |

|

|

| |

FactoryEquipment.com are not responsible for the content of submitted or externally produced articles and images.

Click

here to email FactoryEquipment.com about any errors or omissions contained within this article. |

| |

|

|

|

|

|

|