|

|

|

|

|

|

| |

Digital food for thought: Smart factories and the use of AI from an automation perspective

15

June

2020

|

| |

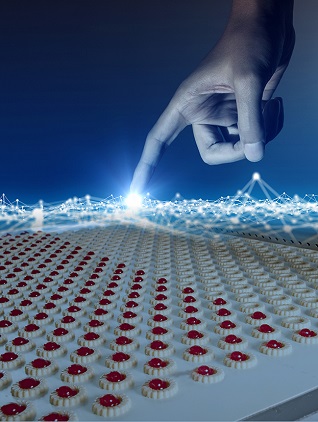

Factory automation has traditionally provided the food industry with faster, more reliable and cleaner production capacity - however, with the advent of the smart factory and commercial AI the factory of the very near future is starting to make production efficiency improvement decisions itself.

Factory automation has traditionally provided the food industry with faster, more reliable and cleaner production capacity - however, with the advent of the smart factory and commercial AI the factory of the very near future is starting to make production efficiency improvement decisions itself.

The first stage of becoming a smart factory is digital network communication, having the right data infrastructure allows companies to create, move and use that data efficiently. With the swift movement and processing of data comes homogeneous control and fast responsive manufacturing, which in-turn justifies investment in the latest automation technology.

Getting the most from a Smart factory is then a case of being aware of the possibilities, this is where using state-of-the-art technology such as AI can already improve the performance and efficiency of factory equipment and human resources.

The role of the Industrial Internet of Things (IIoT)

The role of the IIoT in today’s factory is to connect customer demand to a fast and flexible production facility. Once a purchase decision is made then any increase in the speed of response from the manufacturer is a competitive advantage. If the IIoT offers us one thing, then it is the ability to define customer demand instantly and adapt production to suit.

Companies that can be flexible enough to move away from large batch production can also avoid the cost of large stock holding, both at the manufacturer and throughout the distribution chain. Customisation is already a unique selling point for a large number of consumer goods. The food industry is following suit with individual printing and marking options being designed into many new products.

Customisation equals profitability in both cases. The transfer of data from a sales operation to a manufacturing site, out to the suppliers and then simultaneously back to the distribution and retail network is the key to responsive, flexible manufacturing. To achieve ‘batch size one’ profitably and efficiently we must have the connectivity that the IIoT offers.

The ability to generate, record, transfer and process a large amount of data reliably and efficiently has other benefits. It enables a higher degree of traceability for example, serialisation is already essential for many food, pharmaceutical and consumer products. Better information also allows for continuous improvement and process optimisations at a micro and macro level, generating multiple opportunities for increased efficiency and cost reduction.

Artificial Intelligence (AI) in context

AI is still at the beginning of its journey but we can expect it to have a substantial impact on the industrial environment over the next few years. AI is a perfect fit for manufacturing and leading companies are now integrating various AI functions into factory automation equipment.

Advanced Analytics (AA) and Artificial Intelligence (AI) technologies are extending traditional machine control architectures with more advanced data processing, learning and decision-making capacity. The objective is to deliver increased productivity, efficiency, reliability and accuracy, as well as opening up new possibilities for machine control.

AI can, for example, be a driver for increased productivity. Today, most machines are still built to work within defined margins of capability – perhaps to allow for different loads or speeds or safety ranges. AI technology using deep learning algorithms within the control system enables machines to be driven right up to and even beyond today’s margins, significantly boosting productivity without compromising reliability and quality.

Applying AI principles to individual machine processes can already help to reduce auto-adjustment times, synchronise increasingly complex systems and offer helpful suggestions to operators. It can even enable autonomous decisions to be made based on measured data in real-time, further optimising the process.

Making reliable predictions based on experience, evidence and guidelines is a fundamental function of human intelligence. AI is no different in this respect, it can contribute toward more effective predictive maintenance, monitoring the condition of components to enable replacement before damage occurs, so preventing unplanned downtime.

We see this already but deep learning algorithms are pushing the boundaries further, calculating with more accuracy how long a component can run before replacement. Maybe even compensating for delivery times on replacement parts by slowing the machine down slightly to increase longevity rather than stopping the production line completely.

Similarly, the combination for AA and AI can be a driver for increased efficiencies right across the production environment and here we get into the realm of Big Data Analysis. AA and AI technologies enable different machine states to be recorded and analysed in real time to recognise the current machine status, detect potential faults on the horizon and immediately offer recommendations for actions to the machine operator or autonomously initiate remedial actions.

Reaping the maximum benefit from this development will depend on control systems that not only embed these technologies but which also provide higher levels of connectivity. If the full spectrum of data sources on the plant floor can be connected to Edge Computing platforms for efficient processing for example and on to MIS/MES and ERP systems, then the full benefits of AA and AI are realised. This level of integration enables a far greater range of KPIs to be analysed and so can be used to drive improvements in overall equipment effectiveness (OEE).

What we see then, with control systems built around AA and AI technologies, are machines that are self-learning and self-optimising. The importance of Artificial Intelligence to the machine control market cannot be overstated. In addition to developing products that incorporate a connection to cloud based AI as a service, IBM’s Watson for example, Mitsubishi Electric for one has developed several in-house AI algorithms and services and is positioning its developments in AI technologies under its own brand to reflect its growing importance.

Processing at the Edge

Managing the crossover between Information Technology (IT) and Operational Technology (OT) is the next major challenge. The successful merge of these worlds needs to address the skills gap that has traditionally existed between FA experts and IT departments. Historically the OT layer is managed by automation engineers who do not necessarily have extensive IT skills, while programmers and IT system architects may not completely understand the automation world.

It is worth it though – the most recent technology developments are based on edge computing, which provides the answer by bridging the gap between IT systems and plant level automation. Edge devices can collect and analyse data from neighbouring automation systems and make decisions in real time to influence the production process.

Using this technology effectively can provide a huge competitive advantage. It also creates new challenges: from system compatibility to data security. On the other hand, edge computing systems can be easily interconnected with cloud services to provide scalable data storage and management solutions. In this way users have all the benefits of IT systems, without storage issues or being influenced by potential threats.

Looking after your assets

Against the backdrop of a desire to increase OEE by means of digitalisation, there is a high demand for analysis of extracted data (data mining) from production. The condition and operating profile of plant automation devices and machines for example like a production robot’s components such as servo drives can be recorded. This provides valuable information for example the status of wear parts and any contamination.

The resulting database information then enables predictive maintenance strategies with a significant saving potential in maintenance costs. To improve these strategies further, edge computing technology [as described earlier] is being used to leverage the value of manufacturer’s data using advanced analytic algorithms executed on the Edge of the shop floor.

Another important category of process data is the one that is used for traceability and consumer information, especially in the food sector. This can be employed, for example, to prove compliance with the cold chain or to attach origin information to food packaging that can be called up via a QR code. Data collected from PLCs, controls and drives centrally and processed locally using edge computing reduces the bill for storage space in the cloud in addition to delivering many other advantages for faster production control and monitoring.

Predicting the future

AI is certainly playing a key role in manufacturing, moving from vision recognition to skill learning and predictive maintenance for failure prevention, however it has further scope for providing operational benefits and efficiencies. When detecting impending faults and informing operators how to fix problems for example we see AI again coming to the fore.

AI is being used to increase the effectiveness of predictive maintenance for plant automation assets. Cloud-based solutions using AI platforms analyse operational data and can optimise maintenance regimes based on actual usage and wear characteristics. Predictive maintenance for plant automation assets can of course reduce operational costs, increase asset productivity and improve process efficiency.

For more information, please contact:

Mitsubishi Electric Europe B.V.

Automation Systems Division

Travellers Lane

Hatfield

Hertfordshire

AL10 8XB

Tel: +44 (0) 1707 288769

Fax: +44 (0) 1707 278695

Email: automation@meuk.mee.com

Web: www.gb3a.mitsubishielectric.com |

|

|

| |

FactoryEquipment.com are not responsible for the content of submitted or externally produced articles and images.

Click

here to email FactoryEquipment.com about any errors or omissions contained within this article. |

| |

|

|

|

|

|

|