|

|

|

|

|

|

| |

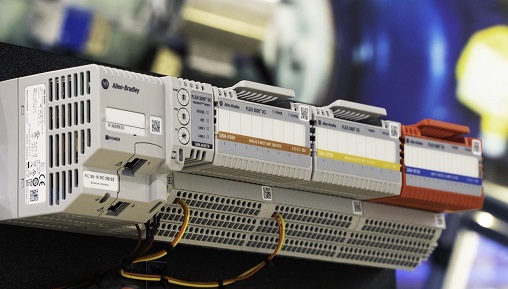

New Allen-Bradley FLEX 5000 HART I/O saves design and maintenance time

17

September

2020

|

| |

Design and controls engineers can now more easily access, configure and manage HART devices using the new Allen-Bradley FLEX 5000 highly integrated HART I/O modules. The simplified programming experience, available with the Studio 5000 Logix Designer application, can help simplify design, maintenance and operational productivity.

Design and controls engineers can now more easily access, configure and manage HART devices using the new Allen-Bradley FLEX 5000 highly integrated HART I/O modules. The simplified programming experience, available with the Studio 5000 Logix Designer application, can help simplify design, maintenance and operational productivity.

Integration between the new I/O modules and HART devices can enhance device management, improve diagnostics coverage and provide real-time device health monitoring. The ability to add and replace process devices online can also reduce downtime and improve productivity.

When a machine is being developed, common data structures and tight integration of instruction sets in the PlantPAx 5.0 system and above can minimize design and engineering time. And once a machine is operational, the

FLEX 5000 highly integrated HART I/O modules can improve overall operational efficiency through increased uptime. A central design environment allows all this work to happen in one place for a smooth user experience and increased productivity.

Meeting more application demands, Rockwell Automation has expanded the FLEX 5000 I/O options to include support for high-density digital, AC and serial modules. The expanded portfolio further enhances standard and safety I/O control in one platform for extreme temperatures.

For more information, please contact:

Rockwell Automation Ltd

Tel: +44 1908 627889

Email: EPopova@ra.rockwell.com

Web: www.rockwellautomation.com |

|

|

| |

FactoryEquipment.com are not responsible for the content of submitted or externally produced articles and images.

Click

here to email FactoryEquipment.com about any errors or omissions contained within this article. |

| |

|

|

|

|

|

|