|

|

|

|

|

|

| |

Covid-19 Social distancing solutions: Distributor turns manufacturer.

26

March

2021

|

| |

Turck Banner Limited is widely known as the daughter company of both Turck and Banner two of the largest sensor and automation manufacturers in the world. Turck Banner’s systems division has a reputation for bringing together a diverse array of products to form cohesive systems solving the requirements of major industrial companies. However they have not manufactured their own product in the UK until July of this year when they started manufacturing systems to support social distancing and occupancy for shops and factories.

Turck Banner Limited is widely known as the daughter company of both Turck and Banner two of the largest sensor and automation manufacturers in the world. Turck Banner’s systems division has a reputation for bringing together a diverse array of products to form cohesive systems solving the requirements of major industrial companies. However they have not manufactured their own product in the UK until July of this year when they started manufacturing systems to support social distancing and occupancy for shops and factories.

Ian Manning (Marketing Manager for Turck Banner) tells their story.

Early on in this Covid-19 lockdown we saw an opportunity where we could support shopkeepers with their need to control the flow of customers entering their premises. We had all stood outside a shop unsure whether it was safe to enter or not. We had also avoided shops with a long queue, choosing an alternative with a shorter wait time. During an online meeting the challenge was given to our systems team to come up with a solution. There were four criteria, it needed to be simple to use, easy to fit, low cost and adaptable to changing government rules.

Two solutions emerged, the first was a simple combination of a power plug, an inline changeover switch and a red- green tower light. The light could be mounted in the shop door or window and the switch placed near the till. The shopkeeper could then turn the light red or green, like a traffic light, to allow customers into the shop or request that they wait. This could be sold for just £90.

The second solution replaced the mechanical switch with a remote control, again allowing the shopkeeper to turn the light red or green. This had a higher price at £210 but reduced the installation requirements.

We trialled both systems at a variety of shops and found the greatest challenge to the systems was the general public. People were not used to any sort of automation controlling the entrance to shops, as they were too busy trying to peer inside, to see if it was safe to enter, to notice the light and signage. The light needed to be more prominent, mounting it outside the shop could be a solution, however this would require permanent installation work. Temporarily running cables around some shops was also challenging.

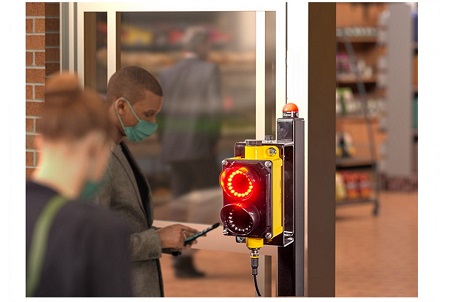

Using feedback from the trials, the systems division developed a standalone cordless control station. It used the remote control, the most popular of the original designs. The tower light was replaced by a daylight visible red / green traffic light mounted on a 1.5m post and a base containing a rechargeable battery and the remote controller. The station is weatherproof and is placed outside the entrance. The traffic light gives a clear instruction to enter or wait, and a repeater indicator is located on top of the pole to ensure that the shopkeeper can see if the traffic light colour is red or green from 360 degrees. At the close of business the station is taken inside the shop and placed on charge for the next day, although the battery will last for more than two days in operation. This solution still cost just under £500 and requires no installation.

Trials of the new system proved to be much more successful. When the station was placed prominently outside the entrance to the shop, customers would enter or wait at the command of the shopkeeper. Queues were kept to a minimum and the shopkeeper had complete control of the number of individuals or families in the premises.

The systems division then turned their attention to our more usual, industrial, customers to see how this may be of benefit to them and whether the station could be adapted for their needs. Two opportunities to assist were identified.

Customers required monitoring of enclosed spaces to ensure safe occupancy and to maintain social distancing on stairways.

Many enclosed spaces now have a reduced occupancy. Those where you couldn’t simply leave the door open for people to see how many were inside, like changing rooms and toilets, needed some sort of external control. The occupancy version of the control station has sensors mounted to the post which detect the presence and direction of a person entering or exiting the room. Rotary dials, on the base, allow the maximum occupancy to be set to between 1 and 99. The indicator lights turn red when the maximum occupancy has been reached, returning to green when the occupancy drops below the maximum.

The second requirement of maintaining social distancing on stairs needed another solution. Most stairways have become one way to avoid people crossing, but for a number of our customers, people were still bunching and not allowing enough space before starting upon the stairs.

The Stair version of the control station is fitted with a single sensor which detects anyone passing as they start upon the stairs, at which time the indicator light turns red for a set period of time before returning to green. The default setting is 4 seconds which produces an average space of 2 metres between people but is adjustable to between 1 and 15 seconds.

We set up a dedicated Web-Shop to make it easy for customers to purchase these solutions.

Other solutions have been developed for different applications such as a system for maintaining a clean work area which instructs users to clean the work area on a pre-set schedule and records the user acknowledgment of when this has been completed.

Everyone has had to make changes because of Covid-19. Turck Banner have added manufacturing to their capabilities. Companies need to do more than, just make the changes required to protect their staff. They need to take this opportunity to see what improvements can be made in order to emerge from this pandemic as a better company.

Peter Gardner, (managing Director, Turck Banner Ltd) said “In these times when many people are struggling it feels good to be able to support local businesses both in providing solutions and by procuring as many parts as we could locally and manufacturing locally.”

For more information, please contact:

Ian Manning

Turck Banner Ltd

Blenheim House

Blenheim Court

Wickford

Essex

SS11 8YT

Tel: +44 (0)1268 578888

Email enquiries@turckbanner.com

Web: www.turckbanner.co.uk |

|

|

| |

FactoryEquipment.com are not responsible for the content of submitted or externally produced articles and images.

Click

here to email FactoryEquipment.com about any errors or omissions contained within this article. |

| |

|

|

|

|

|

|