|

|

|

|

|

|

| |

The leaner, greener and meaner approach to sustainability within the warehouse

9

July

2021

|

| |

Sustainability is high on the media and business agenda, having firmly rooted itself in the minds and strategies of businesses worldwide. Where supply chain logistics is concerned, sustainability is defined simply as looking into how various parts of a logistics network can be improved in terms of optimising business risk, environmental considerations and waste costs. But with pressures increasing on businesses to prioritise sustainability – particularly to address environmental concerns – what steps can businesses take to not just meet these requirements, but also realise economic sustainability benefits as a result? Alexander Baal, Director of Sales Operations at Jungheinrich in the UK, discusses the roadmap that businesses should seek to adopt in order to achieve environmental and economic business sustainability.

Sustainability is high on the media and business agenda, having firmly rooted itself in the minds and strategies of businesses worldwide. Where supply chain logistics is concerned, sustainability is defined simply as looking into how various parts of a logistics network can be improved in terms of optimising business risk, environmental considerations and waste costs. But with pressures increasing on businesses to prioritise sustainability – particularly to address environmental concerns – what steps can businesses take to not just meet these requirements, but also realise economic sustainability benefits as a result? Alexander Baal, Director of Sales Operations at Jungheinrich in the UK, discusses the roadmap that businesses should seek to adopt in order to achieve environmental and economic business sustainability.

The sustainable journey begins

Three elements to consider when it comes to business sustainability within supply chains are social, economical and environmental. However, in the warehouse, businesses should start with addressing the economical and environmental factors as a priority.

The environmental pillar often gets the most attention with government pressure higher than ever on companies to reduce their carbon footprints, electrical or water usage and their overall impact on the environment. For example, the removal of the Red Diesel business entitlement in 2022 means that many companies will need to quickly overhaul their diesel equipment and consider more energy efficient power alternatives.

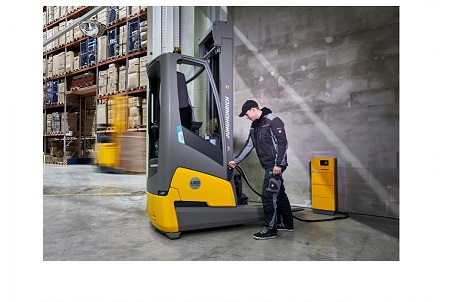

But while this may appear to be a logistical headache, those companies that invest in their environmental CSR efforts also find this also unlocks significant financial benefits. For example, businesses using materials handling equipment that is powered by lithium-ion batteries have found that having a beneficial impact on the planet can also deliver productivity and efficiency benefits, such as opportunity charging and supporting 24x7 operations – ultimately increasing profits and therefore ensuring sustainable business continuity.

The economic pillar provides a counterweight to challenging measures that corporations are pushed to adopt, such as abandoning fossil fuels rather than phasing in changes. In today’s robust competitive industry and turbulent economic environment, most factories need to readjust their strategy to produce as many products as possible at a minimal cost. The goal is to make the production process more efficient, productive and ultimately – sustainable. So, what remedies can businesses take to improve not just their environmental credentials, but also their bottom line?

The catalyst for automation

Pre-pandemic, the concept of innovating to survive was for some businesses not a core focus. However, COVID-19 and the global economic shut down that ensued in 2020 has accelerated the need and demand to operate in a seamless fashion, whilst also ensuring that companies are prepared for any potential disruption in the future. Due to lockdowns, social distancing, combined with changing consumer habits such as the rise of ecommerce, today’s warehouses must now look to find ways to operate effortlessly and economically while adhering to new post-pandemic health and safety protocols.

The reality of COVID-19 and its impact on the warehouse and supply chain management industry has uncovered gaps and inefficiencies in supply chain and warehouse automation strategy. But these types of hurdles have served as the catalyst for warehouse managers to adopt and implement automation technology, to shift and adapt to peaks in demand and the need for efficiency.

Warehouse automation drives value, but although robotics aid the warehouse for the monotonous tasks such as picking, packing and transporting, they can never replace humans to do the more intricate tasks such as reparation and analysing. This will not only provide ROI and continuity during a crisis like the current pandemic, but in the long-term to meet long-lasting business goals as well.

Pre-pandemic, automation was viewed as a luxury; now it’s a necessity. With the booming e-commerce intralogistics market, warehouse managers can’t afford to let productivity slide. They need to have a strategy that involves automation to create leaner, greener and more streamlined operations while continuing to contribute to sustainability.

Reduce, Reuse, Recycle

Lithium-ion is at the forefront of the electric transport and energy storage revolution. Businesses already using lithium-ion can continue to demonstrate and grow their environmental credentials through productivity and efficiency gains. As with all batteries, those from electric vehicles are eventually destined for recycling.

The energy storage market is growing dramatically. As we see storage becoming increasingly competitive and common, its applications and business cases will diversify which bodes well for opportunities for second-life battery systems.

By deploying lithium-ion batteries in a secondary market application, such as deploying a wall charge solution with second-life batteries to supplement charge from the grid, the environmental footprint created by their manufacture, both in terms of metals extraction and energy required in production, can be significantly minimised. Especially with lithium-ion it allows the opportunity to charge for a longer lifetime, with higher energy density thus increasing the lifespan of the equipment.

The European Commission acknowledges that batteries will play a fundamental role in delivering the EU’s 2050 net-zero ambition, which will be delivered through the Green Deal policy. Driven by transport demand as well as by industrial uses, the EU is forecast to account for 17 percent of global lithium-ion battery demand by 2030, making it the second-biggest market globally.

However, to ensure a competitive and sustainable industry, businesses should encourage reuse, improving batteries collection and recycling of materials. The Green Deal Policy objectives are to strengthen the functioning of the internal market, spanning battery products, processes and waste batteries, by ensuring a level playing field through a common set of rules, promote a circular economy and reduce environmental and social impacts throughout all stages of the battery life cycle.

Conclusion

As globalisation intensifies, companies face several obstacles, including increasing global competition, growing consumer demands and expectations, rising personnel costs and increasing environmental regulations. In light of these challenges, and by adopting environmental, social, and economic perspectives in strategy planning and execution, companies are seeking to harness environmentally friendly and efficient measures to respond to challenges that further maximise their business landscapes in an all round sustainable way.

For more information, please contact:

Benedikt Nufer

Jungheinrich AG

Schnackenburgallee 24

22525 Hamburg

Germany

Tel: +49 40 8532430

Email: benedikt.nufer@jungheinrich.de

Web: www.jungheinrich.com |

|

|

| |

FactoryEquipment.com are not responsible for the content of submitted or externally produced articles and images.

Click

here to email FactoryEquipment.com about any errors or omissions contained within this article. |

| |

|

|

|

|

|

|